NSN 5325-00-085-6453

Part Details | RETAINING RING

5325-00-085-6453 A resilient metal item, circular or nearly circular, which is designed to be inserted into an internal or external groove and retained by its own spring action, or it may have external prongs or projections designed to be inserted into a hole and retained by spring action of the prongs which grip by imbedding into the material. For items having internal prongs which perform the same function, see PUSH ON NUT. It is used to keep and/or lock a part(s) in position, as a ball bearing on a shaft or in a housing. See also CLIP, RETAINING and PIN, LOCK. Excludes RING, CONNECTING, ROUND.

Alternate Parts: WST150CA, WST-150-CA, RST150C, RST-150C, 106064251, 10606425-1, 5325-00-085-6453, 00-085-6453, 5325000856453, 000856453

| Supply Group (FSG) | NSN Assigned | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 53 | JAN 01, 1963 | 00-085-6453 | 07623 ( RING, RETAINING ) |

REFERENCE DRAWINGS & PICTURES

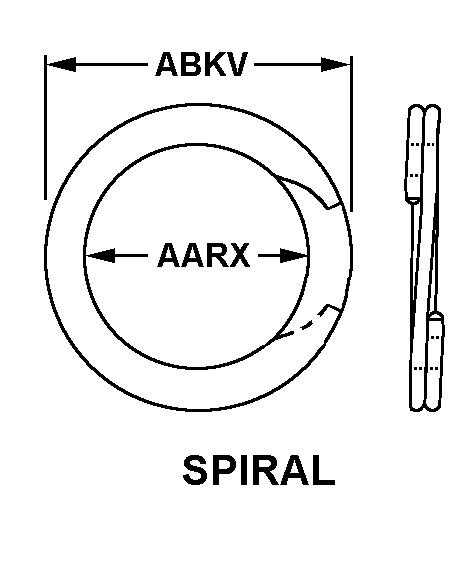

ROUND

SPIRAL

Cross Reference | NSN 5325-00-085-6453

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| WST-150-CA | 51814 | SMALLEY STEEL RING CO. |

| RST-150C | 80756 | SPIROLOX, INC. |

| 10606425-1 | 18876 | U S ARMY AVIATION AND MISSILECOMMAND |

Technical Data | NSN 5325-00-085-6453

| Characteristic | Specifications |

|---|---|

| MATERIAL | 0$DST1572$4$5$8$DST1080$DST1084$DST1085$DST1086$DST1090 |

| STRENGTH RATING | 211000.0 POUNDS PER SQUARE INCH MINIMUM TENSILE |

| CASEHARDENING INDICATOR | NOT CASEHARDENED |

| RING STYLE | SPIRAL |

| CROSS-SECTIONAL SHAPE STYLE | 2 ROUND |

| USAGE DESIGN | EXTERNAL |

| MATERIAL DOCUMENT AND CLASSIFICATION | BFED STD 66, COMP 1070$CFED STD 66, COMP 1072$DFED STD 66, COMP 1074$EFED STD 66, COMP 1075$FFED STD 66, COMP 1078$HFED STD 66, COMP 1080$JFED STD 66, COMP 1084$KFED STD 66, COMP 1085$LFED STD 66, COMP 1086$MFED STD 66, COMP 1090 AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) 2ND MATERIAL RESPONSE |

| SURFACE TREATMENT | CADMIUM |

| INSIDE DIAMETER | 1.408 INCHES MINIMUM AND 1.423 INCHES MAXIMUM |

| OUTSIDE DIAMETER | 1.614 INCHES MINIMUM AND 1.629 INCHES MAXIMUM |

| MAJOR THICKNESS | 0.048 INCHES MINIMUM AND 0.052 INCHES MAXIMUM |